Testing

Quality is not an Act. It is a Habit.

To ensure 100% conformance to customer requirements the part goes through multiple stages of testing throughout its supply chain. With the help of our in-house test setup and network of NABL certified labs, we can perform a range of tests for raw materials, chemicals, and mechanical properties; verification, validation of coated, plated, and welded samples, microstructure analysis, NDT, dimensional inspection, and several other tests based on project requirement on case basis. Few commonly performed tests include :

A minimum number of test samples are sliced off from the parent material and checked in the lab for its chemical composition. The chemical composition is verified by spectrometry, PMI (Positive Material Identification) etc. The analysis of mechanical properties includes hardness, strength, and toughness.

The microstructure is checked to check for any defects or abnormalities in the raw material. It gives more clarity w.r.t the processing and quality of the material. It is done to evaluate the grain structure, determine the porosity, contamination and oxide content, bonding of coated/plated material and abnormalities present etc.

It is usually done in the intermediary or final stages of manufacturing to ascertain compliance throughout the product life cycle. We perform LPT (Liquid Penetrant Test), UT (Ultrasonic Testing), MPI (Magnetic Particle Inspection), X-ray and PMI to check coating, welding, and machining defects.

Part development is carried out through APQP (Advanced Product Quality Planning) and FAI (First Article Inspection) is done on CMM (Coordinate Measuring Machine). Based on the production volume and complexity of part a mix of attribute and variable inspection instruments are used. An ERP integrated calibration control system ensures 100% availability of calibrated instruments which are fit for use. The credibility of our inspection is ensured by our qualified quality inspectors who are certified through periodic MSA techniques.

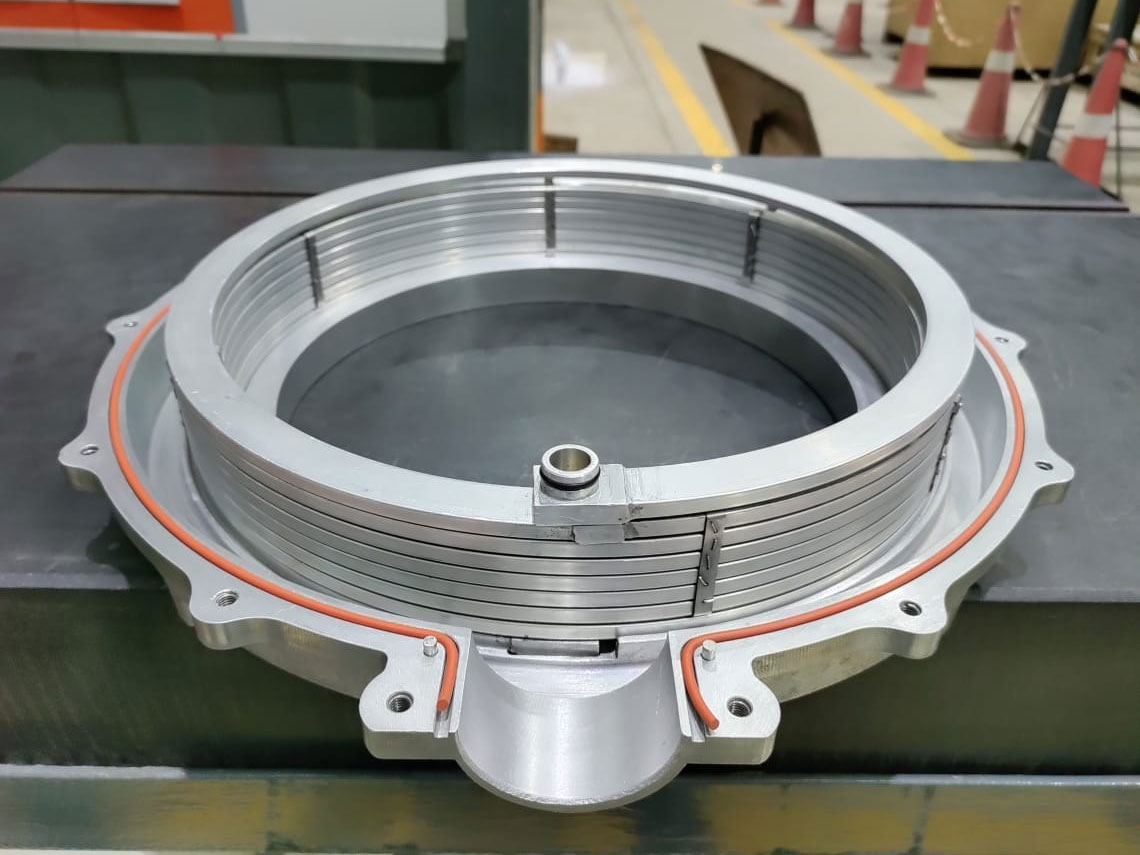

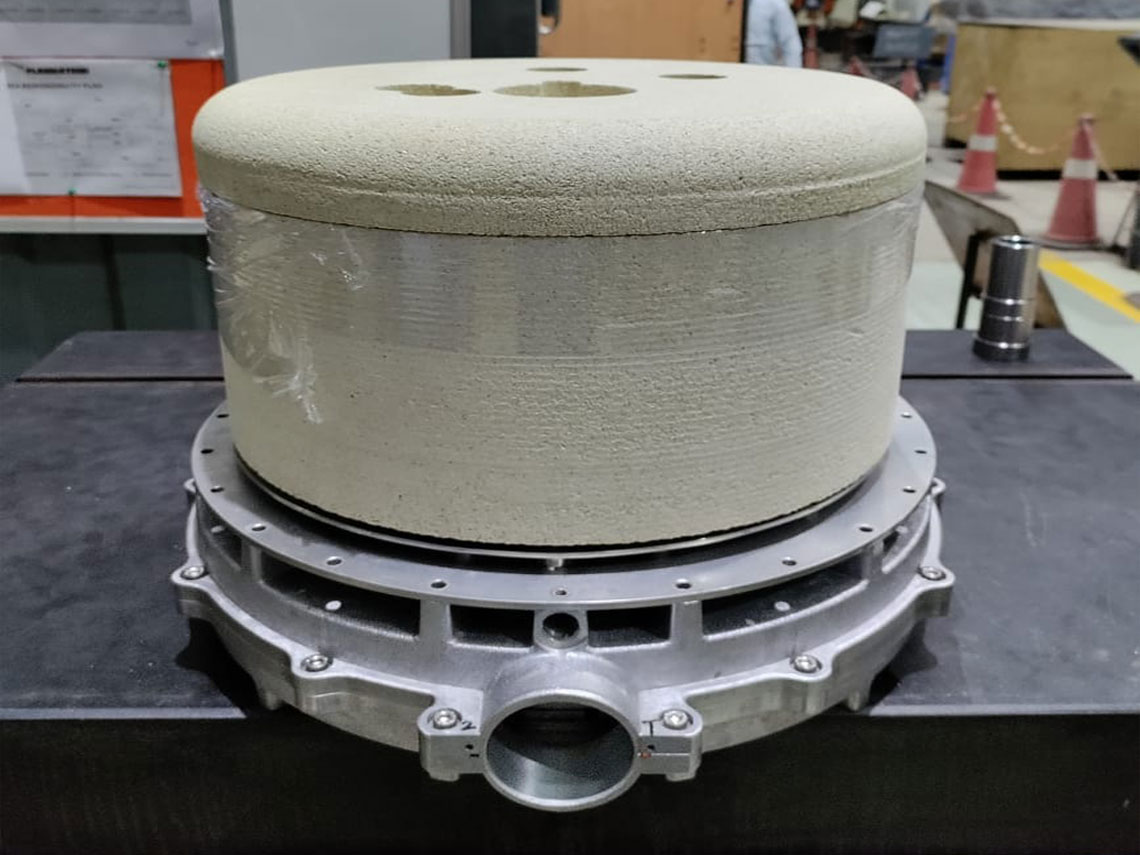

We can make customized test rigs based on the part/project requirement. The test rig can be designed to simulate the actual operating conditions and evaluate the overall part performance.

Assembly

Delivering Results, Reliability and complete Dependability

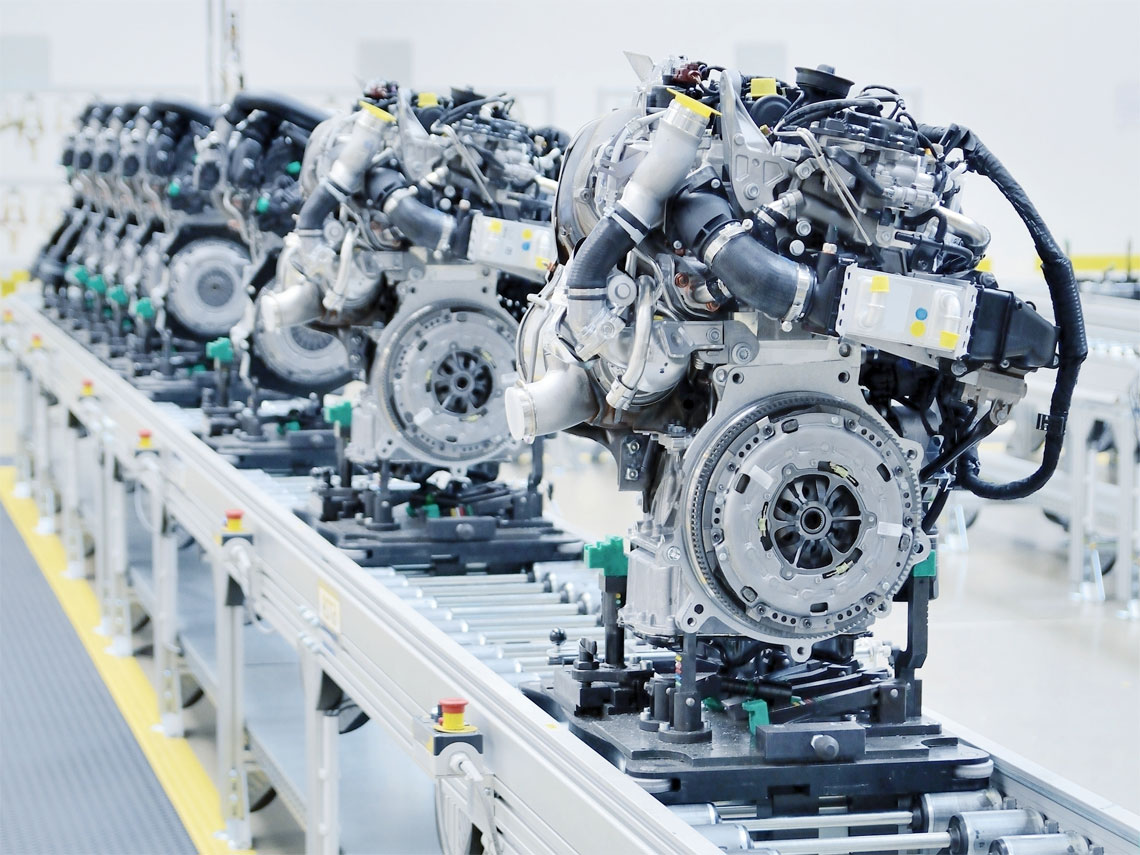

Assembly is often a very cumbersome and time-consuming process with a long list of checkpoints to comply with. The time invested in this stage is unpredictable and often neglected during the project estimation phase. Also, each part which goes inside the assembly is received at different timelines from each vendor which indefinitely delays the project and effecting the profitability. We endeavor to take complete responsibility of customer project and provide finished assemblies ready to put in operation.

How do we do it?

A synopsis of our Skills and Expertise

- Understanding the purpose, functioning and inter-relation of each part in the assembly

- Breaking down the main assembly to its sub-assembly and individual parts

- Categorization of parts based on its type, material, lead time etc.

- Create a BOM and prepare an MRP (Material Requirement Planning) in the ERP system

- Detailed risk assessment of each part to account for uncertainties

- Defining the manufacturing, inspection, testing, and validation method

- Creating project timeline-based lead time for each part and continually optimizing it to meet the targeted schedule defined by the customer

- Project implementation with continuous analysis and problem resolution based on live reports generated through ERP

- Identification on each part to ensure traceability and documentation of each process

- Customer access to live tracking of project status

- Final testing and inspection of parts to enable generation of COC (Certificate of Conformance)

- Inspection by customer representative or third party appointed agency

- Timely availability of parts for final assembly through KANBAN system

- Ensuring 100% uptime of assembly station through TPM implementation

- Customized and automated assembly stations designed to meet the targeted TAT

- Packaging and shipping of product as per customer specified standards

- Complete project performance tracking through ERP

- Review of part/project history at any time through barcode scanning

How does it benefit you?

Gain an Advantage over your Competition

- You will receive finished product ready for delivery/installation

- Significant saving of time and money for assembly

- Avoid the hassle of managing multiple vendors and related intangible costs

- Reduced SCM activity will allow you to optimize your fixed internal costs

- Avoid delays during the last mile of project execution

- Saving on SCM cost will make your product more competitive and profitable in the market

- Complete transparency of project execution will keep you updated and give you the virtual experience of in-house manufacturing

Frequently Asked Questions

Got Questions? We’ve Got Answers!

- We provide a variety of testing services, few of which are performed in-house and few outsourced to our qualified service providers. Outsourced test laboratories are NABL accredited and periodically audited for conformance to international standards. For more details, please refer the Testing section of this page.

- The testing of final part or assembly is utmost important to validate and approve. Testing requirements are reviewed for feasibility during the RFQ stage.

- Initial and intermediary tests such as raw material chemical and mechanical testing, dimensional and NDT are identified at every stage and performed as per specifications provided by the client.

- Functional and Performance based tests of the final part/assembly will however depend upon the overall scale and scope of the project. We can make customized test rigs and fixtures to simulate the actual testing conditions as required by the client and provide certified test results.

- The inspections and tests carried out at every stage as per QAP, is recorded in our DMS (Data Management System).

- The test certificates mandated by the client are identified and listed during our internal review process. Standard to be followed for testing and information to be displayed on the certificate is also noted.

- The test certificates are submitted to the client at intermediary and final stage for review and approval. The parts are packed and shipped only post clearance from the client.