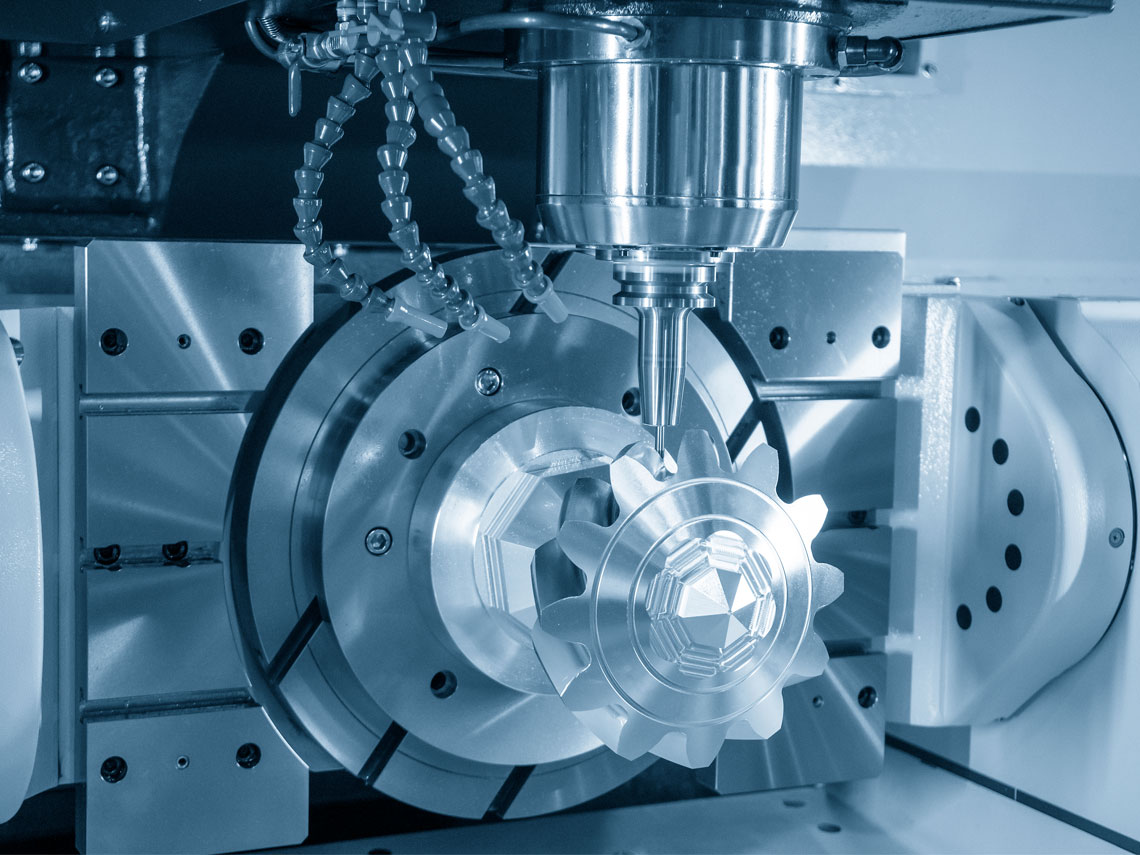

Process Overview

Adopting the latest Technology for Efficient and Reliable Manufacturing

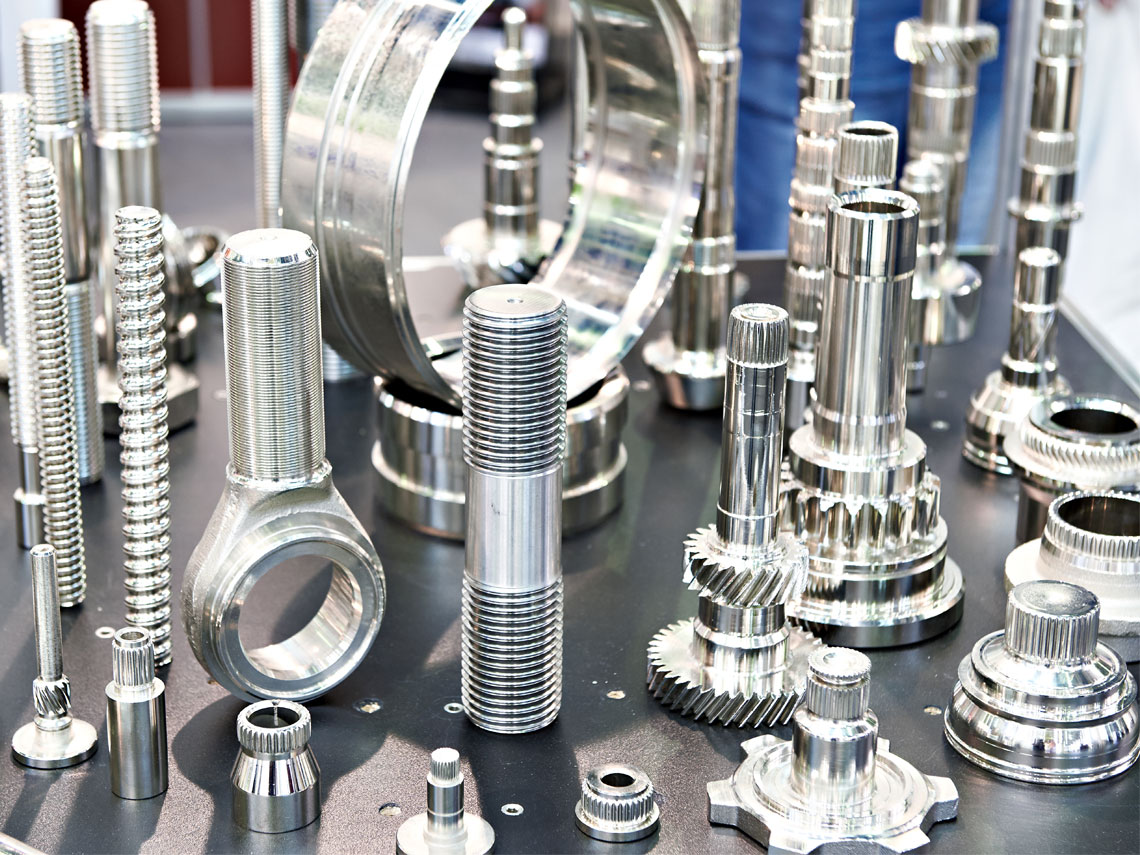

It is a process that creates a desired shape and size by removing the unwanted material from a larger piece of metal i.e Subtractive Manufacturing. A plethora of machining options are available depending on the part geometry, profile to be achieved, GD & T requirements, surface finish, throughput etc. CNC (Computer Numerical Controlled) machining is a widely used manufacturing process that uses automated high-speed cutting tools to form a particular feature from metal or plastic. CNCs are generally classified as 3-axis, 4-axis and 5-axis based on the movement of part and tooling along the axis. Different machines have different working mechanism such as :

a) workpiece securely clamped while the tool moves

b) tool may remain in place while the workpiece moves

c) both the cutting tool and workpiece move together

Materials

Commodities that we emulsify into Finished product

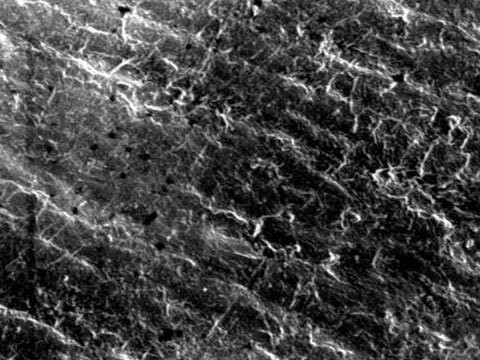

Metals

Carbon Steel Alloys

Stainless Steel Alloys

Titanium Alloys

Zinc Alloys

Copper Alloys

Brass Alloys

Bronze Steels

Nickel and Cobalt Alloys

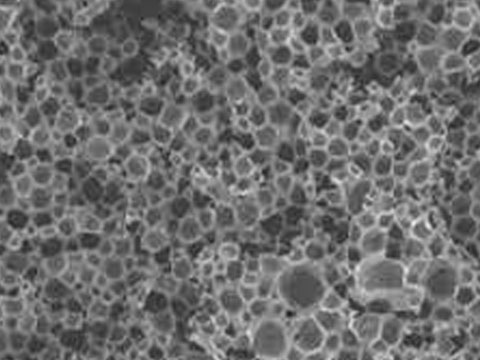

Plastics

ABS

(PTFE) Nylon

Polypropylene

Polycarbonate

PVC

HDPE

Capabilities

A synopsis of our Skills and Expertise

- Prototype to high volume production of up to thousands of parts per year based on part configuration

- CNC machining of parts weighing up to 10 Tonnes

- CNC machining of parts measuring up to 1000mm Dia and 4000mm Length

- Small and big sized VMC machines up to X axis – 4000mm, Y axis – 2000mm and Z axis – 1000mm

- Cylindrical Grinding of parts up to 800mm Dia and 6000mm Length

- Conventional turning of parts up to 1500mm Dia and 6000mm Length

- Supporting machining operations such as Cutting, Deep hole drilling, Milling, Boring, Broaching, Gear hobbing, Surface grinding etc.

- Machining of wide variety of material grades such as Carbon steel, Alloy steel, Tool steel, Non-ferrous alloys, and Superalloys

- Machining of castings and forgings of small to large sized parts

- Tight tolerance of machined parts up to ± 0.005mm

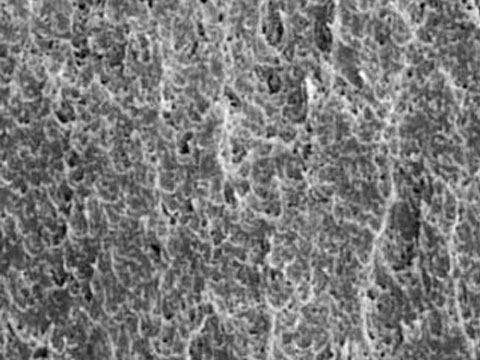

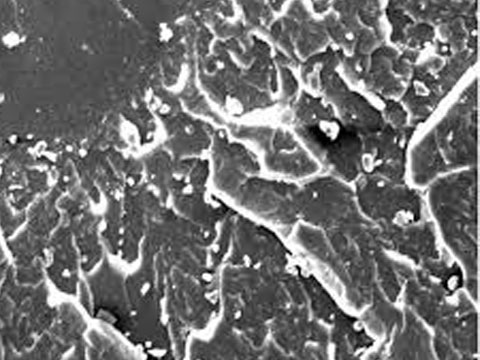

- Post-machining surface finishing operations such as ID and OD polishing, Superfinishing, Honing etc.

- Surface treatment processes such as plating, anodizing, phosphating, blackodizing, thermal spray coating, slurry coating, polymer painting etc.

- CMM inspection for part validation and approval of machined parts

- ERP notified calibration control system for measuring/monitoring instruments and machines

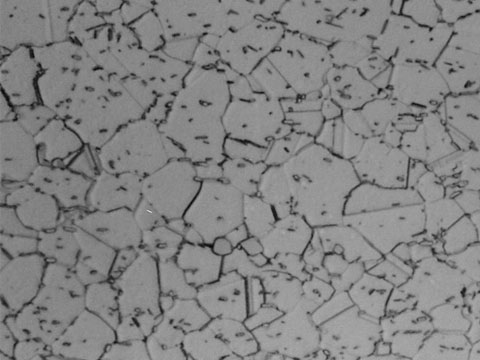

- In-house lab tests carried out for raw material verification at production site, certified to NABL standards

- Complete NDT testing of parts for defect analysis pre and post machining as per international standards

- Customer appointed third party inspection and verification allowed

- Manufacturing facility certified to IATF 16949 and AS 9100 Rev.D Quality Management System

- Implementation of Lean Six Sigma tools for better quality control, process control, part traceability and documentation

- Industry 4.0 integrated manufacturing facilities

Application and Benefits

Gain an Advantage over your Competition

- We supply machined components to almost all industry sectors in batch and mass production quantities. The design and functional characteristics of the part are fixed based on its end application. Selection of the material is done to sustain the working environment and machined to accurate dimensions to ensure proper fit and assembly.

- Usually, Aerospace engine parts are made from Titanium, Tantalum and Nickel based alloys which exhibit high strength, low weight and high temperature fatigue resistance.

- Similarly, parts used in Oil & Gas and Power Generation sectors are made from Nickel, Chrome and Cobalt based alloy steels which exhibit high wear and corrosion resistance.

-

Few key benefits of machining include :

- Rapid Tooling – A variety of materials can be machined to achieve accurate dimensions for making fixtures and molds.

- Rapid Prototyping – Flexibility of manufacturing small scale prototypes saves a lot of time, money and effort and enables to conduct a detailed part validation and risk assessment.

- Production – Reliability and Repeatability of machining can be ensured by application of advanced process control techniques which enables mass production.

- Customization – Wide range of advanced manufacturing techniques increases the scope of customization for new part development.

Frequently Asked Questions

Got Questions? We’ve Got Answers!

- Traditional machining involves removal or forming of metal from a stock manually, by a skilled machinist. The stock is mounted on the machine with the help of chuck, vice, fixtures, steady rest and a variety of cutting tools made of hardened steel, carbide and other grades are used to machine the metal.

- CNC machine performs the same function but the only difference being it is computer numeric control rather than manual control by a machinist. The programmer writes the code as to control the movement of the tool mounted on the turret which in turn performs the machining operation. The different operating parameters (speed, feed, rpm, depth of cut etc.) can be modified based on the material and dimensional requirements.

- CNC machined parts are more precise, accurate and have better repeatability. They are usually preferred for high volume production as it gives a better throughput. Parts which are to be made in close tolerance are preferably manufactured on CNC machine.

-

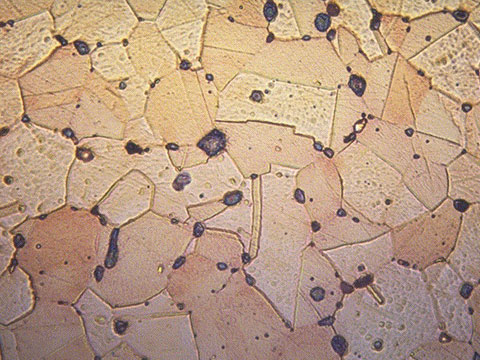

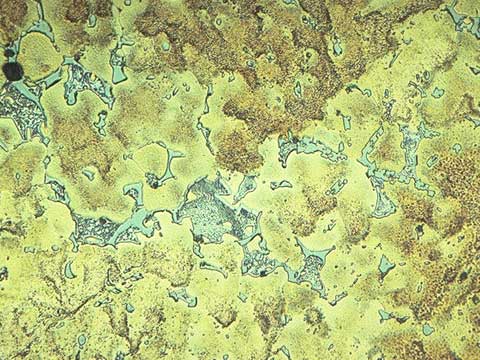

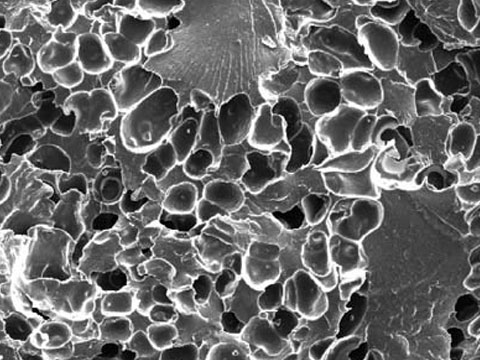

Due to complexities in the investment casting process, numerous defects can be observed such as :

- We can perform almost all kinds of machining operations such as turning, milling, drilling, broaching, ECM/EDM, CNC turning, vertical turning, VMC machining (with and without 4th axis), 5 axis VMC machining, boring, deep hole drilling, polishing, grinding (flat and cylindrical), honing, burnishing, superfinishing and many more.

- We have developed and keep upgrading our capabilities by adding professional and experienced vetted suppliers to our vendor network. Please refer to Capability section of this page for more details.

- The machining process is analyzed based on Process Capability Analysis. CTQ’s are defined for the part as per the requirement of the drawing. Batches are prepared based on the quantity of production order and the actual CTQ dimensions are mapped on the run chart after inspection. Suitable action is taken based on the trend analysis to ensure the parts are produced within the defined control limits.

- Control Charts is the most simple and effective way of producing conforming parts with the highest degree of consistency. This process is followed by us as part of PPAP (Production Part Approval Process) based on project requirement or as requested by the Client.

- The final drawing and specifications provided by the Client during order finalization is taken as a reference for manufacturing the parts. The CTQ dimensions are key characteristics are defined.

- The parts are inspected at every stage and after it is finish machined using calibrated measuring instruments such as micrometers, verniers, gauges etc.

- Critical parts are also inspected using sophisticated measuring equipment’s such as CMM (Coordinate Measuring Machine), profile meter, microscope, and NDT instruments.

- We can manufacture parts as small as 1” in diameter and length and ranging up to 60” in diameter and 300” in length.

- We can make a variety of parts such as sleeves, mandrels, piston rods, plungers, domes, screws and barrels, flanges, spindles, diffusers, scrolls, shafts etc.

- There is no restriction as to the type of part we manufacture as long as we are able to meet the design requirements through our diversified machining capabilities.

- CNC machining allows us to achieve tight tolerance of up to ±0.05mm. The accuracy achieved also depends on the machine selection, fixturing, process consumables and operating parameters.

- Higher accuracy of up to ±0.005mm can be achieved by grinding, polishing, honing etc.

- We can make a variety of parts for the Automotive and Aerospace industry which are critical and have stringent quality norms.

- Other sectors where we provide machined parts include Oil & Gas, Steel, Power Generation, Plastic Extrusion, Marine, Pumps, Valves etc.